Smart screw installation – Access angle to implant screws

Using digital modelling, installing implants has been made easier through “guided” surgery. Easier from a biological point of view that is, because esthetically, optimization will be sought only if clinical criteria are first respected—which, from a prognostic point of view, makes perfect sense. We can nevertheless state that surgical requirements are not always in line with the patient’s expectations.

A problem often encountered in the laboratory is that the access hole to the abutment screw is located in the esthetic area of the tooth. To resolve this, we can simply cement the crown to the abutment, which makes the position of the access hole irrelevant. To maintain the benefit of having a screw-retained restoration, we use a secondary screw, which allows us to place it where we want on the abutment. Many manufacturers already have prefabricated angled abutments with a second screw opening, created specifically for this purpose. There is also a completely personalized method in which experienced technicians can drill a second threaded bore where desired, and add a screw seat in the porcelain-fused-to-metal (PFM) crown to come.

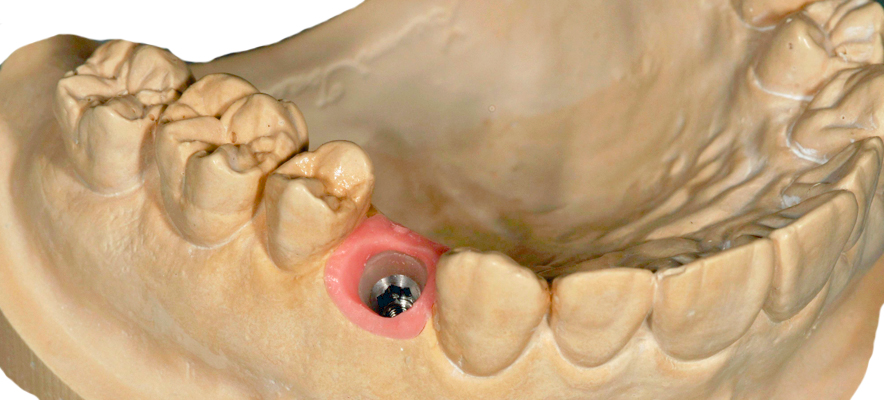

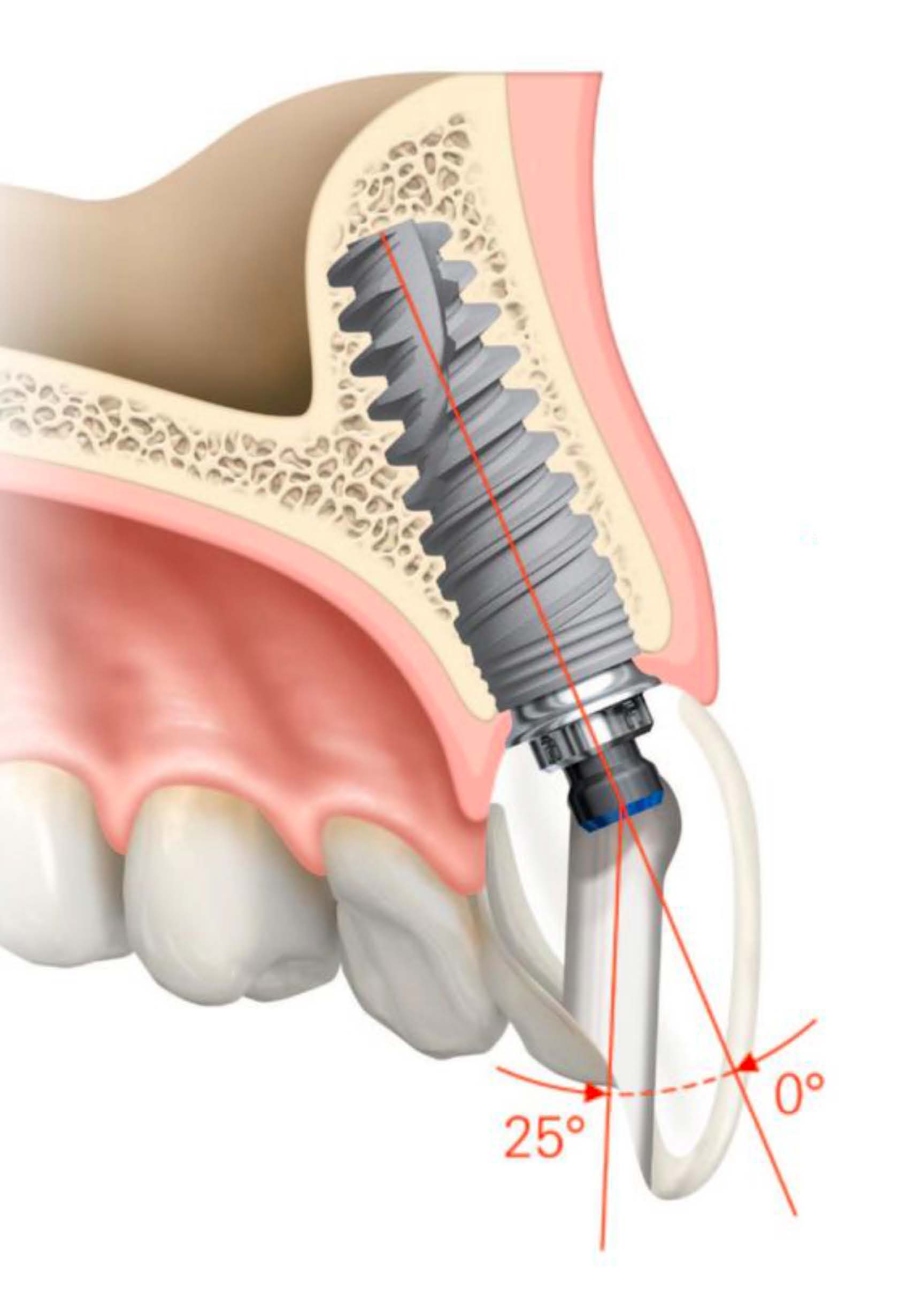

Here is a situation where the implant (position 24) is well integrated, but the overall angle is preventing the crown from being screwed in directly.

An anatomical simulation gives a clearer picture of the esthetic challenge.

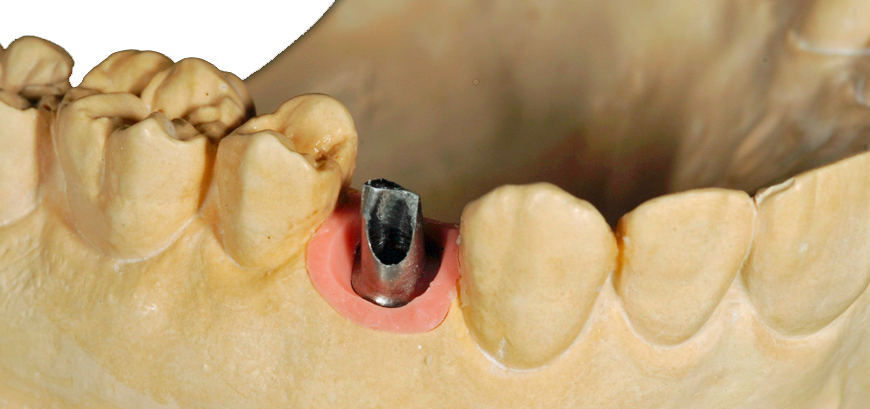

We create a second hole on the lingual side of the metal abutment, and we bore to create threads that will receive the secondary screw.

This technique clearly provides greater flexibility for those (and there are many) who prefer a screw-retained restoration.

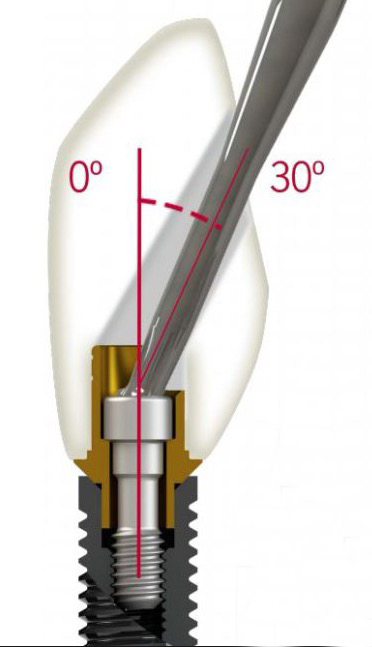

This procedure applies to PFM restorations. How can we deal with this same problem if the requested restoration is made of zirconia? This is where the concept of the angled access hole comes into play. Since zirconia is machined using tridimensional data, all that is required is to give the access hole to the abutment retention screw a caster angle different than 0 ̊, and to use a screwdriver head that allows a good amount of torque to be applied, even if the screwdriver is tilted with respect to the screw itself.

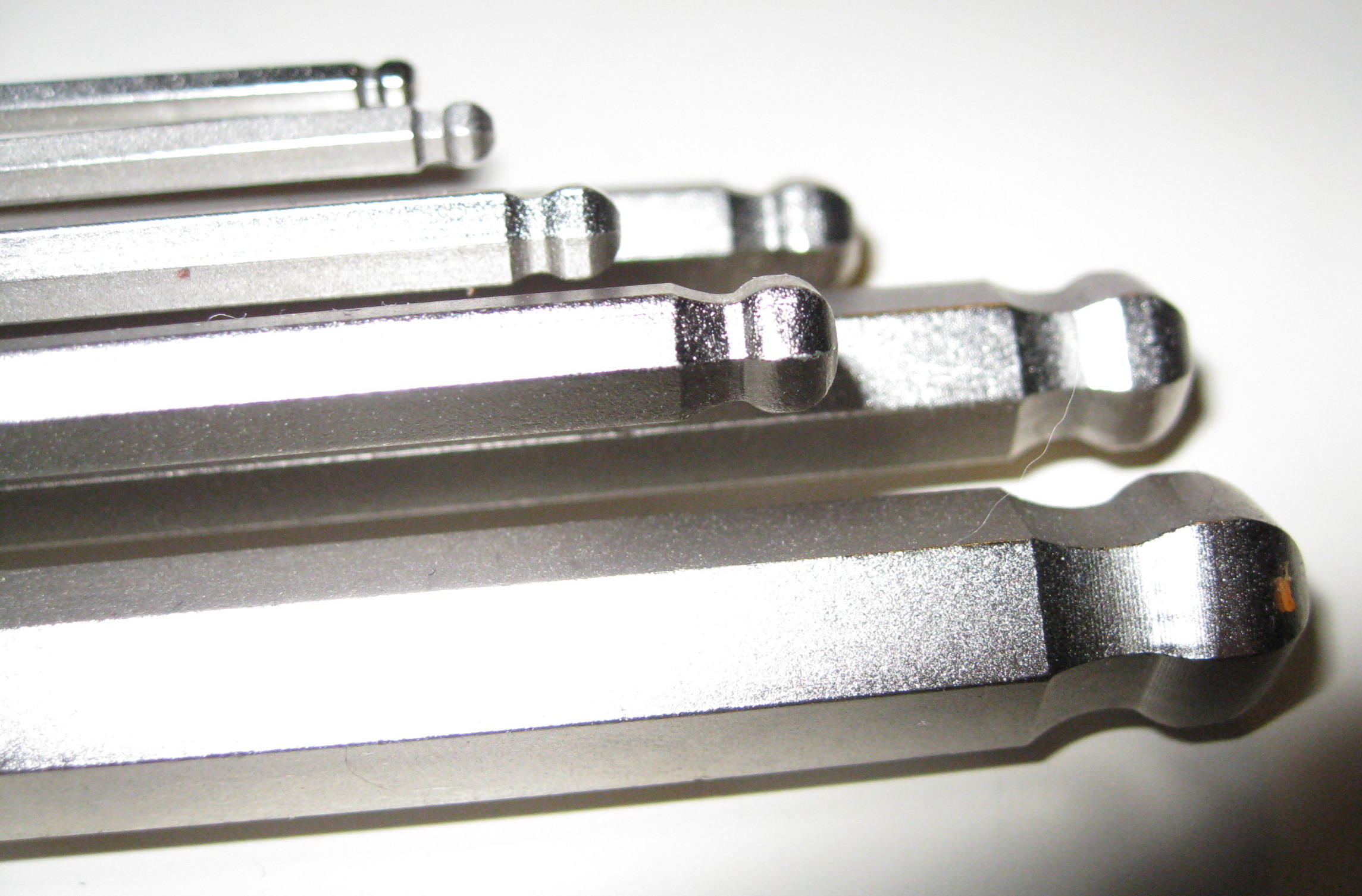

This idea is far from new outside the dental field. Here, we see a set of Allen keys with rounded ends, specifically designed to tighten bolts without having to insert the key in line with the bolt. These Allen keys have been around in hardware stores for a long time, for all kinds of mechanical work.

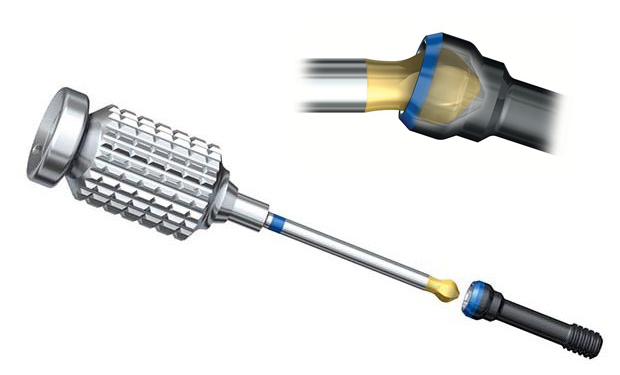

For single-unit C&Bs, Nobel Biocare has innovated with its angulated screw channel (ASC) system.

There is also a third-party manufacturer called Dynamic Abutment Solutions, whose versatile approach uses titanium bases.

This possibility of orienting the access channel as desired considerably increases the use of zirconia for screwed-in restorations, even when the implant angle in the bone is less than ideal. Despite the mandatory purchase of special screwdrivers, when applicable, this solution makes a lot of sense, and is more economical to boot.

This option will soon be widespread. In view of the concept’s success, most of the main manufacturers are moving from the drawing board to the production stage.