Hybrid C&Bs and bonding

The use of hybridized materials is increasingly common in dentistry. In this segment, we will discuss the bonding of titanium with zirconia. Given its intrinsic qualities of biocompatibility, durability and esthetics, zirconium is now widely used to make crowns and bridges. Whenever zirconium is used to restore a tooth with an implant, there is usually a titanium connection between the crown and the implant. Whether you are dealing with a custom-fitted abutment or a prefabricated base, bonding with a resin cement is the method recommended for assembling the two parts.

There are some exceptions, of course.

Some manufacturers make abutments totally out of zirconia, and that includes the connection with the implant. It is best to use this type of abutment for medium- or large-diameter abutments. This optimizes the thickness and durability of the zirconia walls in the implant’s cavity.

In some situations, the titanium component is not being bonded but rather mechanically inserted between the screw seat in the zirconia abutment and the implant itself. Nobel Biocare features this type of connection in its Procera™ line.

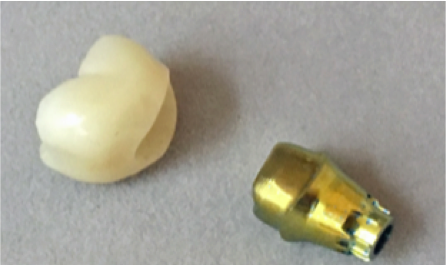

At present, it is common practice to bond the titanium connection to the zirconia in the lab. Whether you are using monolithic or layered feldspathic ceramics, there will be an access hole for the prosthetic screw in an esthetically discreet, non-visible area of the crown, and the entire assembly is then bonded with a cement specially developed for that purpose.

Anodized titanium abutment ready for bonding.

.

The excess bonding agent is left on during the hardening phase, as these cements are usually of the anaerobic type. The darker shadow on the occlusal surface is in fact the screw-access hole.

.

As this excess is also light-cured, you can then simply snap it off to leave a smooth, watertight joint.

Provided certain crucial parameters are met, in situloosening is extremely rare. The particular nature of the new materials involved calls for new ways of doing things. Because the zirconia abutments can only be fabricated via CAD/CAM, hybridization with titanium has resolved some of the issues entailed in connecting them to the implant.