Homothetic supported ceramic crowns

It’s no secret that good work generally yields good results. There are dozens of steps to go through in the laboratory before we have a final product that’s ready to send to the client. Following trade practices and protocols isn’t just sound professional conduct, it’s also the logical thing to do, not to mention the best way to avoid running into problems. If each step in the production process is done properly, we’re more efficient, the technical part of our work is greatly simplified, and, in the long run, we know what the results will be. But, above all, the final product will be highly satisfactory. In short, you’d have to be crazy to make your life more complicated by doing sloppy work.

A crown or a bridge made with different materials must meet several criteria, including being homothetic, meaning that the substructure on which the ceramic will be baked must represent a reduced version of the final tooth. A homothetic base is therefore a crown that provides adequate support for the surface layer of ceramic.

This trait is essential to guarantee the long-term physical integrity of the prosthesis.

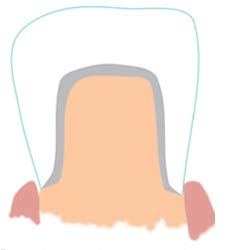

1- The photo on the left shows zirconia coping with no integrated support. The strength and durability of the final crown risk being compromised in the long run.

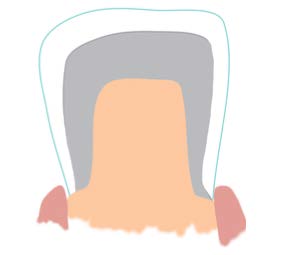

2- In the photo on the right, the zirconia coping was fashioned properly. The esthetic ceramic cap is not left unsupported, ensuring that the final prosthesis will be both solid and attractive to the eye.

Creating the substructure is a crucial step in the crown production chain. The dentist never sees this part of the crown, unless he or she requests it for a trial run of the structure. Whether it’s a handmade porcelain-fused-to-metal crown or a CAD/CAM-produced ceramic-zirconia crown, the prosthetist always needs to make sure to provide adequate support for the layered ceramic.

Looking at the two crowns below, it’s almost impossible to tell which one is made with a homothetic subframe. Yet, both crowns were fashioned from the two substructures shown above.

As you can see, beneath the layers of ceramic that comprise laboratory-made crowns lies tremendous technical expertise. If the here and now were our only concern, we could save ourselves a lot of work by making substructures without any thought to providing adequate support. But the long-term results wouldn’t be so great.

Esthetics are the first thing evaluated when a crown is placed in a patient’s mouth, but don’t forget, there’s always more than meets the eye.